Precision in Production

From Design to Machining

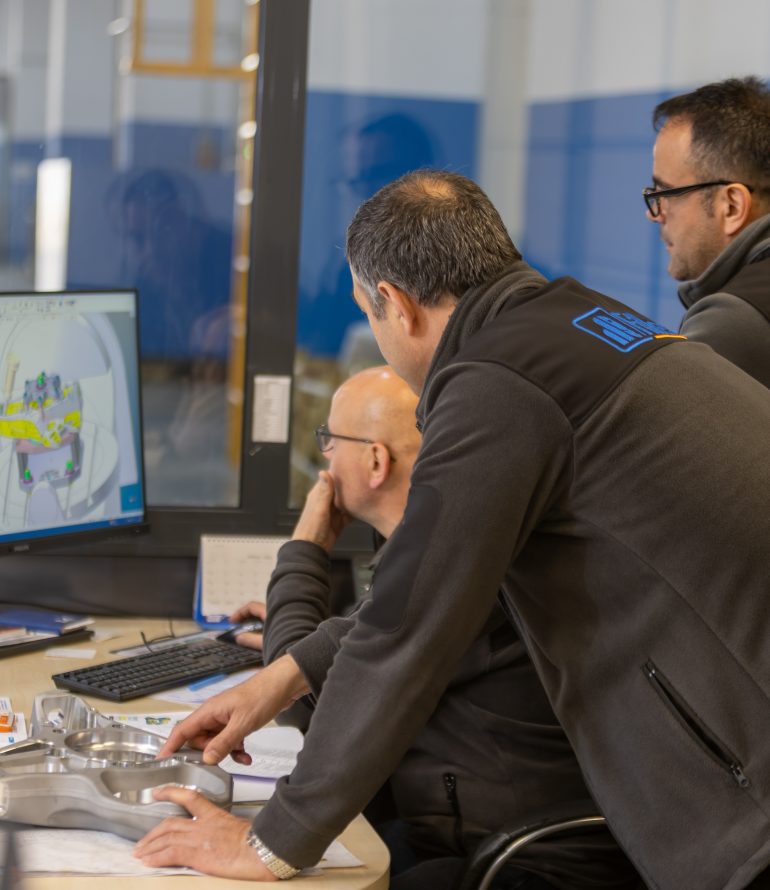

Detailed Analysis and Design

Utilizing Solidworks, we meticulously examine 3D solid models and technical

drawings provided by our customers. This critical step ensures that every

design for production apparatus and fixtures meets the exact technical

specifications, enhancing sustainability and reproducibility.

drawings provided by our customers. This critical step ensures that every

design for production apparatus and fixtures meets the exact technical

specifications, enhancing sustainability and reproducibility.

Strategic Tool Planning

Based on the apparatus & fixture designs and product technical

requirements, we craft precise cutting tool plans. This preparation is crucial

for optimizing the production process and ensuring product quality.

requirements, we craft precise cutting tool plans. This preparation is crucial

for optimizing the production process and ensuring product quality.

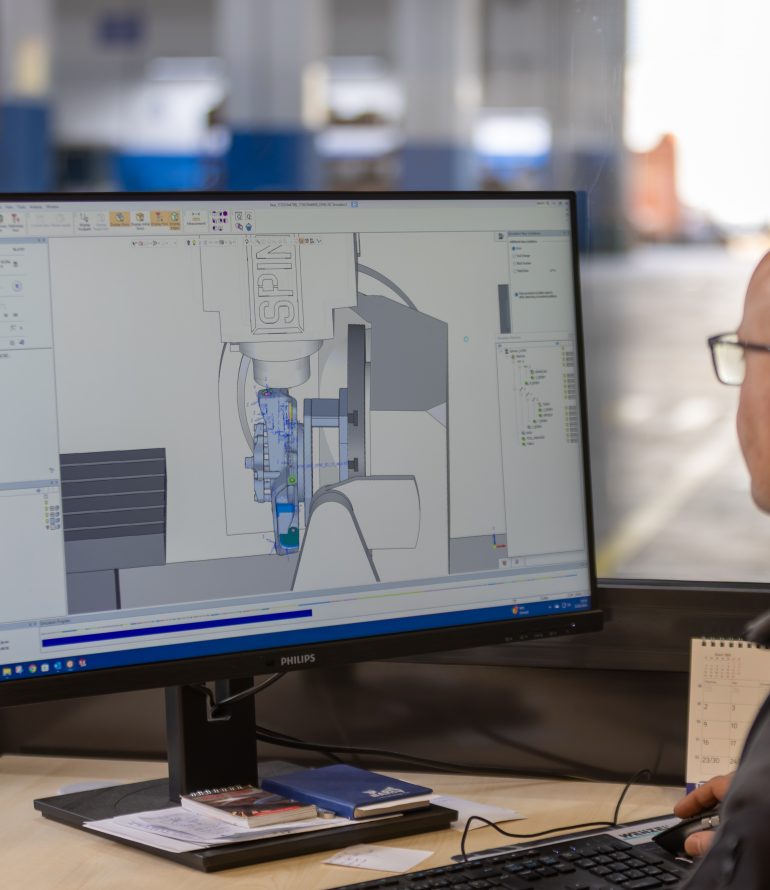

Advanced Programming and Machining

Our skilled team programs the product machining process using Cimatron

CAM software. This program is then seamlessly transferred to our CNC

machining centers, marking the beginning of the precision machining

process.

CAM software. This program is then seamlessly transferred to our CNC

machining centers, marking the beginning of the precision machining

process.

Streamlining Production

Planning to Delivery

Our Manufacturing

and Quality Control

Equipment

Manufacturing Machinery

CNC Lathes: 8 units

CNC Milling Machines: 22 units

CNC Milling Machines: 22 units

Quality Control Room Equipment

CMM (Coordinate Measuring Machines): 2 units

Contour Scanning Device: 1 unit

Surface Roughness Measurement Device: 1 unit

Contour Scanning Device: 1 unit

Surface Roughness Measurement Device: 1 unit